Liquid handling components

Features

Specification

Features

Outstanding performance

−Accuracy: ≤0.5% CV at full stroke

− 0.09ul/increment (for 1000 μL, the resolution is 10,200 increments)

Easy system integration

− Small footprint, the distance between devices can reach 9/18/28mm when installed side by side (based on different models)

− No pipes, valves or syringes. No system fluid, which means no need to start filling,no flushing, no leakage

− Compatible with SOCON disposable tips (10 μL, 50 μL, 200 μL, 1000 μL, with or without filter)

− Intuitive aspiration/dispense volume and speed instructions

− Use programmable baud rate communication via CAN interface

Process and product have high reliability

− Factory calibrated exhaust volume

− Advanced automatic pump diagnosis, self-test and error reporting functions

− Configurable liquid level detection device (optional) with integrated pressure sensor(pLLD)

− Equipped with integrated capacitive liquid level detection hardware (cLLD) (optional)

− Real-time streaming data can be obtained from the process monitoring sensor (optional)

− DiTi pressure sensor (optional)

− DiTi ejector mechanism (optional)

Specification

CAN Step Motor motion controller (SC-DRV421)

Features

Specification

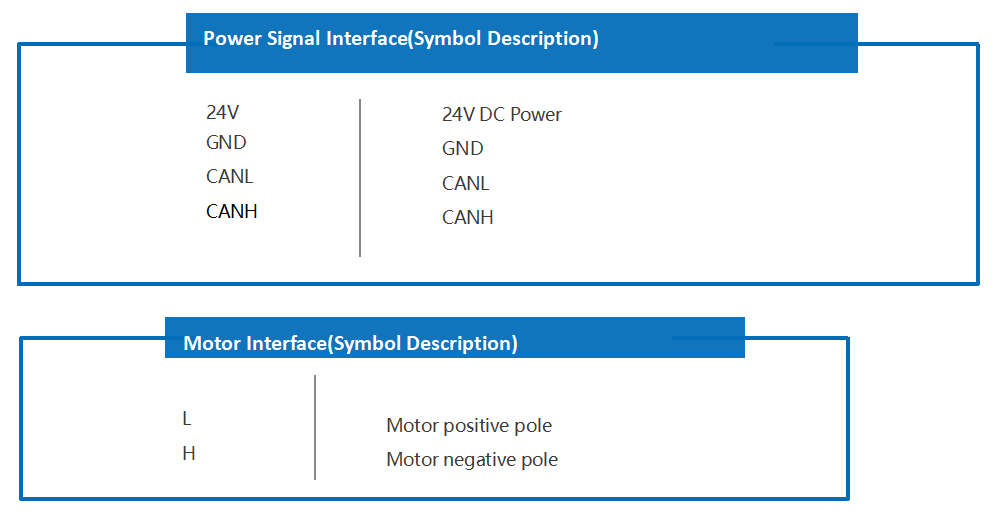

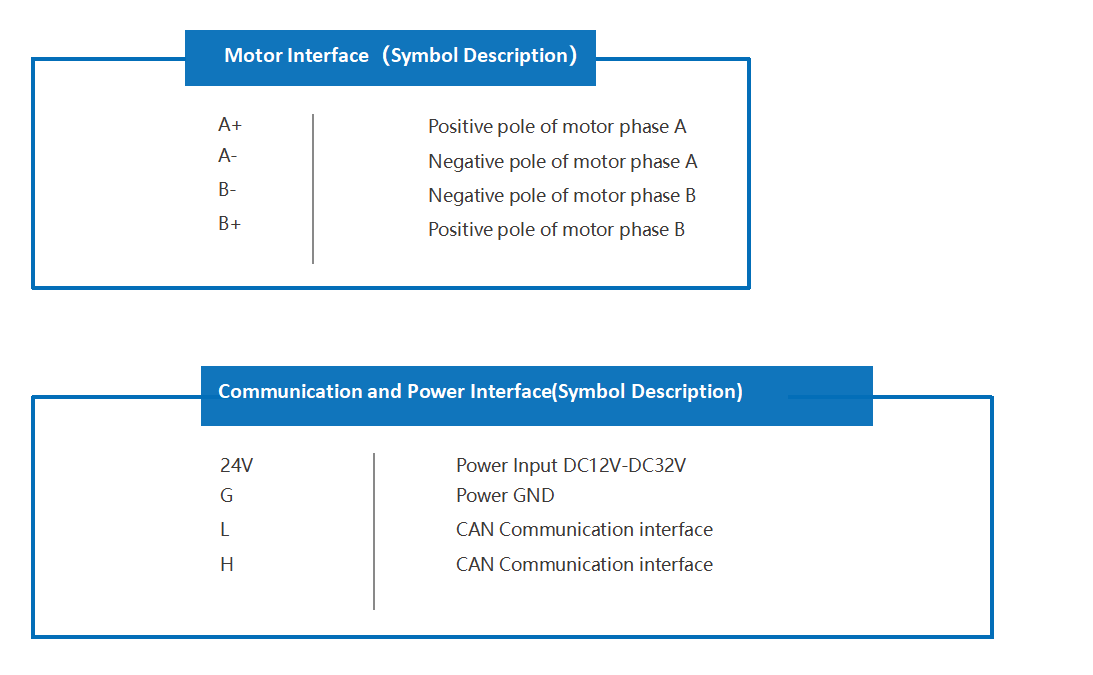

Electric Interface

Features

– Exponential curve algorithm very close to the motor characteristic curve enables smooth running

– Miniature design, easy installation, integration with 42 stepper motors

– Network Distributed Control, CAN2.0 Networking

– Supporting positioning mode and speed mode

– Simple electrical interface and convenient wiring

– Accurate zero position, zero drop action with reset, zero automatic zero calibration

– Limit function, automatic stop when encountering limit signal

– Closed Loop Control with accessible encoding disk

– Able to customize start current, constant speed current, lock current and enable the motor run more smoothly, efficiently at a lower heat

– Provide computer debugging software, facilitate debugging and secondary development

Specification

|

Dimension 42.5mm×42.5mm×20mm |

CAN.ID |

|

Max Peak Current 2.5A |

Max Subdivision |

|

Step Subdivision 1、2、4、8、16、32 |

Star-up Velocity,Acceleration Velocity,Max Velocity |

|

Step Frequency 20Hz-160KHz |

Direction of motion |

|

Electrical Null Position TTL |

Able to implement encoding disk |

|

Storage Temp -20°~85° |

Encoding disk resolution |

|

Thermal-Shutdown, current foldback, overburden protection circuit |

Start-up Current, Uniform Current and Latching Current |

Electric Interface

CAN Step Motor motion controller (SC-TB571)

Features

Technical Specification

Electric Interface

Features

– Exponential curve algorithm very close to the motor characteristic curve enables smooth running

– Network Distributed Control, CAN2.0 Networking

– Supporting positioning mode and speed mode

– Supporting Liquid Level Detection Function

– Simple electrical interface and convenient wiring

– Accurate zero position, zero drop action with reset, zero automatic zero calibration

– Limit function, automatic stop when encountering limit signal

– Closed Loop Control with accessible encoding disk

– Able to customize start current, constant speed current, lock current and enable the motor run more smoothly, efficiently at a lower heat

– Provide computer debugging software, facilitate debugging and secondary development

Technical Specification

|

Dimension 52mm×52mm×22mm |

CAN.ID |

|

Max Peak Current 4.5A |

Max Subdivision |

|

Step Subdivision 1、2、4、8、16 |

Star-up Velocity,Acceleration Velocity,Max Velocity |

|

Step Frequency 20Hz-160KHz |

Direction of motion |

|

Electrical Null Position TTL |

Able to implement encoding disk |

|

Storage Temp -20°~85° |

Encoding disk resolution |

|

Thermal-Shutdown, current foldback, overburden protection circuit |

Start-up Current, Uniform Current and Latching Current |

|

|

Liquid level detection sensitivity |

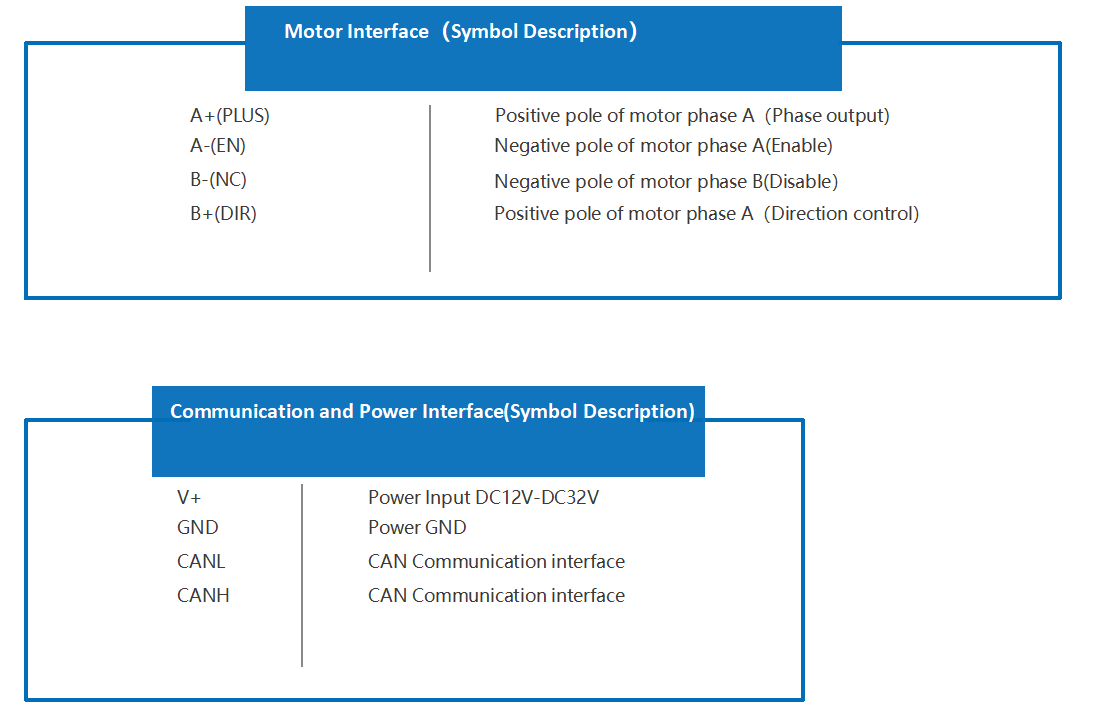

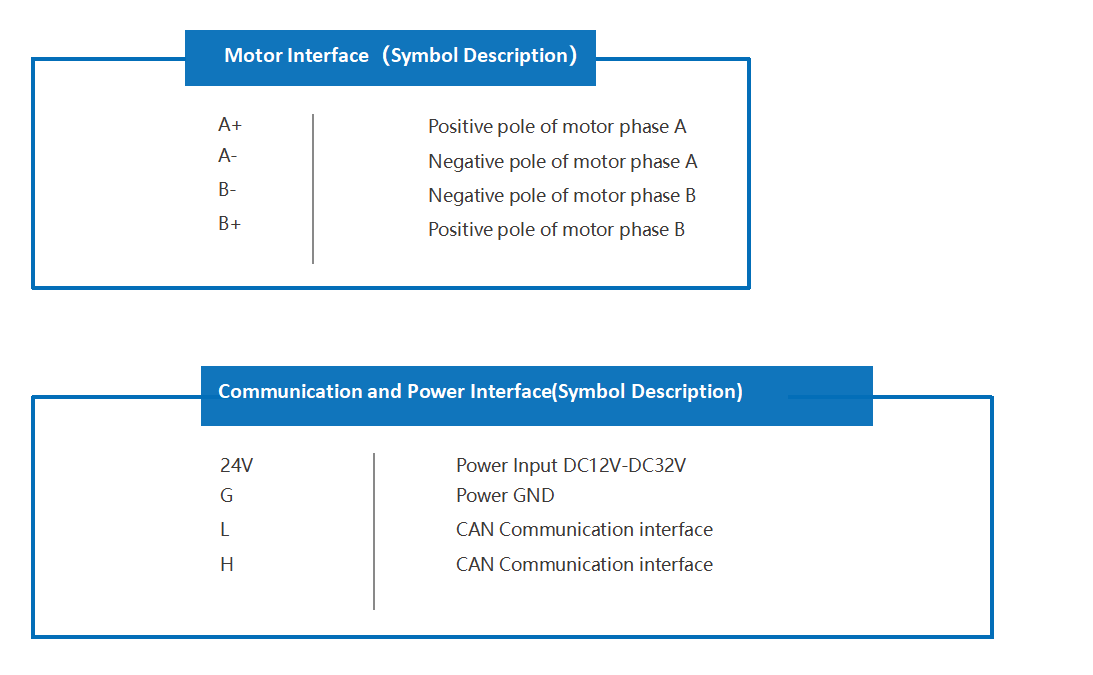

Electric Interface

CAN Dual Step Motor motion controller (SC-TB572)

Features

Technical Specification

Electric Interface

Features

– Exponential curve algorithm very close to the motor characteristic curve enables smooth running

– Network Distributed Control, CAN2.0 Networking

– Supporting positioning mode and speed mode

– Supporting Liquid Level Detection Function

– Simple electrical interface and convenient wiring

– Accurate zero position, zero drop action with reset, zero automatic zero calibration

– Limit function, automatic stop when encountering limit signal

– Closed Loop Control with accessible encoding disk

– Able to customize start current, constant speed current, lock current and enable the motor run more smoothly, efficiently at a lower heat

– Provide computer debugging software, facilitate debugging and secondary development

Technical Specification

|

Dimension 80mm×76mm×25mm |

CAN.ID |

|

Max Peak Current 4.5A |

Max Subdivision |

|

Step Subdivision 1、2、4、8、16 |

Star-up Velocity,Acceleration Velocity,Max Velocity |

|

Step Frequency 20Hz-160KHz |

Direction of motion |

|

Electrical Null Position TTL |

Able to implement encoding disk |

|

Storage Temp -20°~85° |

Encoding disk resolution |

|

Thermal-Shutdown, current foldback, overburden protection circuit |

Start-up Current, Uniform Current and Latching Current |

|

|

Liquid level detection sensitivity |

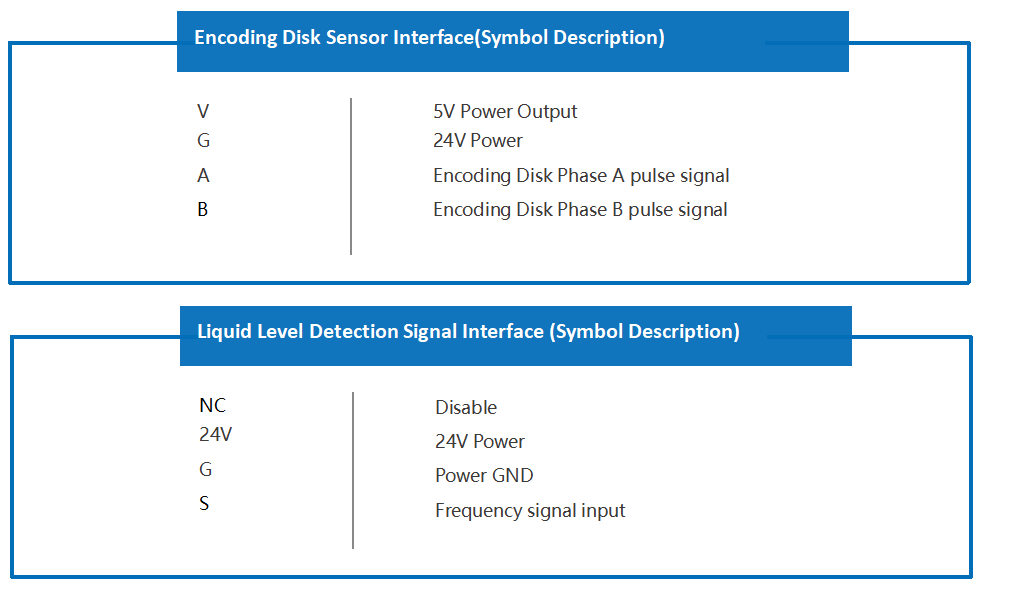

Electric Interface

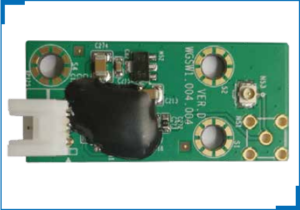

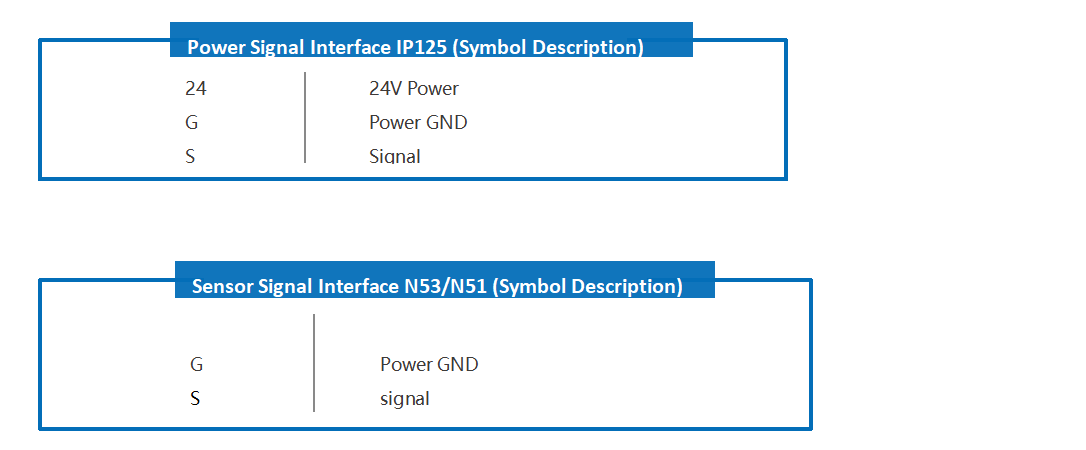

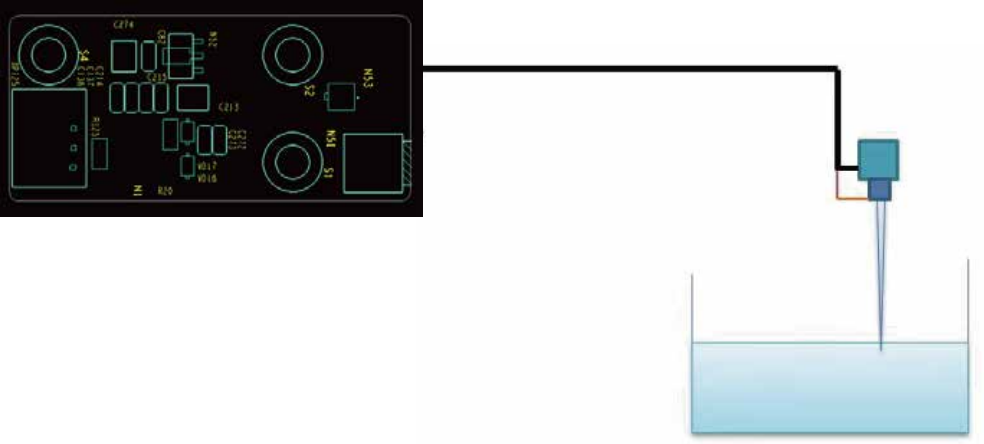

Liquid Level Detection module

Features

Electric Interface

Features

– Capacitance changes below 1pF can be detected

– 24V power supply

– Frequency signal output

– Applicable to all kinds of needle level detection, solution level detection

– Shielding RF113 Cable by IPEX

Electric Interface

Note:The shield layer needs to be suspended and as close as possible to the sensor terminal,connecting the negative pole of the sensor, and connecting the positive pole of the sensor with the core wire.

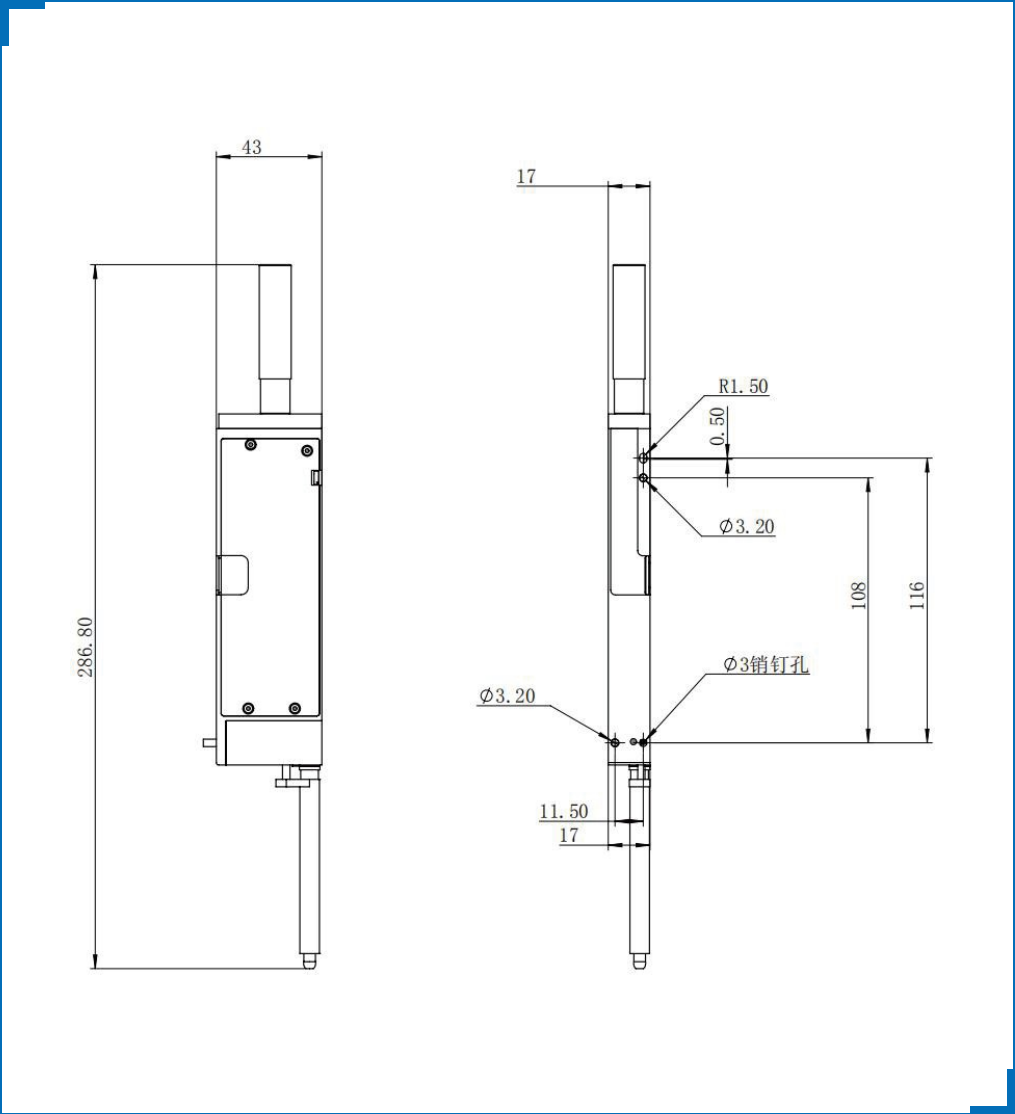

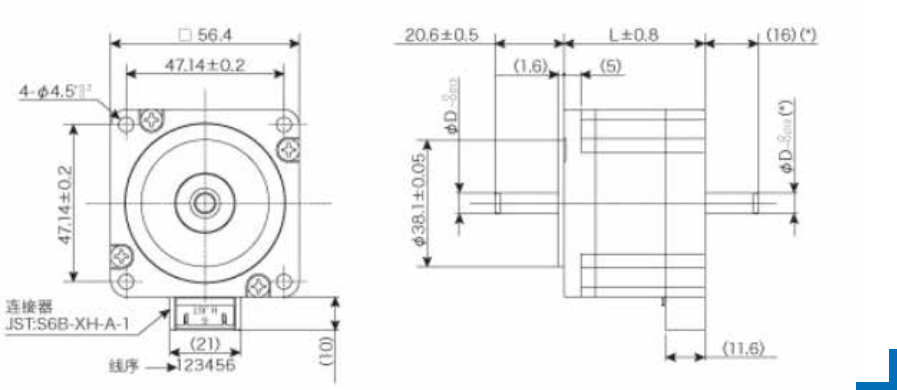

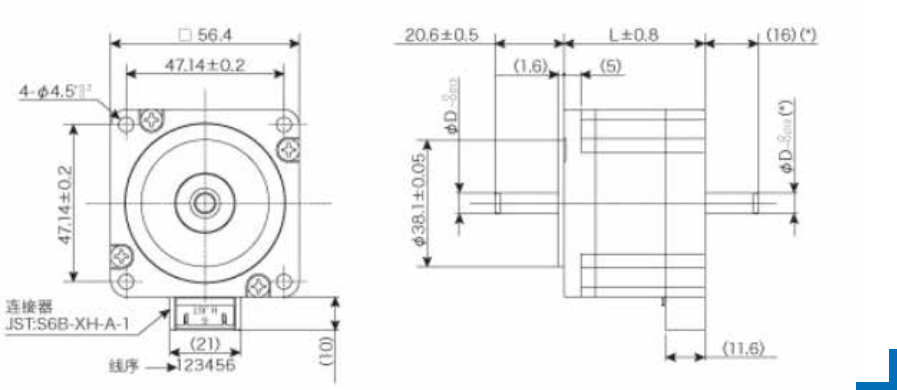

CAN Step Motor All-in-one Unit 43D series

|

Model |

CAN step deg |

Voltage/ V |

Current/A

|

Resistance/Ω |

Inductance/mH |

Holding torque/mN-m |

Moment of inertia/g-cm² |

Pin QTY |

Weight g |

Unit length mm |

|

SST43D104X |

1.8 |

6.8 |

0.57 |

12.00 |

16.0 |

294 |

33 |

4 |

230 |

34 |

|

SST43D106X |

1.8 |

4.9 |

0.85 |

5.75 |

8.1 |

304 |

33 |

4 |

230 |

34 |

|

SST43D108X |

1.8 |

3.6 |

1.13 |

3.20 |

4.9 |

312 |

33 |

4 |

230 |

34 |

|

SST43D110X |

1.8 |

3.0 |

1.41 |

2.10 |

3.3 |

319 |

33 |

4 |

230 |

34 |

|

SST43D112X |

1.8 |

2.3 |

1.70 |

1.35 |

2.3 |

322 |

33 |

4 |

230 |

34 |

|

SST43D115X |

1.8 |

1.9 |

2.12 |

0.90 |

1.5 |

309 |

33 |

4 |

230 |

34 |

|

SST43D204X |

1.8 |

8.6 |

0.57 |

15.00 |

24.0 |

420 |

56 |

4 |

290 |

40 |

|

SST43D206X |

1.8 |

5.1 |

0.85 |

6.00 |

11.8 |

432 |

56 |

4 |

290 |

40 |

|

SST43D208X |

1.8 |

3.9 |

1.13 |

3.45 |

7.1 |

422 |

56 |

4 |

290 |

40 |

|

SST43D210X |

1.8 |

3.4 |

1.41 |

2.40 |

4.8 |

441 |

56 |

4 |

290 |

40 |

|

SST43D212X |

1.8 |

2.8 |

1.70 |

1.65 |

3.6 |

456 |

56 |

4 |

290 |

40 |

|

SST43D214X |

1.8 |

2.3 |

1.98 |

1.15 |

2.5 |

441 |

56 |

4 |

290 |

40 |

|

SST43D216X |

1.8 |

2.1 |

2.26 |

0.95 |

1.8 |

424 |

56 |

4 |

290 |

40 |

59D series

|

Model |

CAN step deg |

Voltage/ V |

Current/A

|

Resistance/Ω |

Inductance/mH |

Holding torque/mN-m |

Moment of inertia/g-cm² |

Pin QTY |

Weight g |

Unit length mm |

|

SST59D110X |

1.8 |

3.3 |

1.4 |

2.35 |

7.5 |

870 |

145 |

4 |

0.51 |

42 |

|

SST59D115X |

1.8 |

2.2 |

2.1 |

1.05 |

3.4 |

870 |

145 |

4 |

0.51 |

42 |

|

SST59D120X |

1.8 |

1.8 |

2.8 |

0.65 |

2.0 |

880 |

145 |

4 |

0.51 |

42 |

|

SST59D125X |

1.8 |

1.5 |

3.5 |

0.43 |

1.3 |

890 |

145 |

4 |

0.51 |

42 |

|

SST59D130X |

1.8 |

1.3 |

4.2 |

0.31 |

0.9 |

870 |

145 |

4 |

0.51 |

42 |

|

SST59D210X |

1.8 |

3.9 |

1.4 |

2.75 |

9.2 |

1200 |

210 |

4 |

0.62 |

48.5 |

|

SST59D215X |

1.8 |

2.5 |

2.1 |

1.20 |

4.1 |

1200 |

210 |

4 |

0.62 |

48.5 |

|

SST59D220X |

1.8 |

2.0 |

2.8 |

0.70 |

2.4 |

1220 |

210 |

4 |

0.62 |

48.5 |

|

SST59D225X |

1.8 |

1.7 |

3.5 |

0.48 |

1.6 |

1240 |

210 |

4 |

0.62 |

48.5 |

|

SST59D230X |

1.8 |

1.4 |

4.2 |

0.34 |

1.1 |

1200 |

210 |

4 |

0.62 |

48.5 |

|

SST59D310X |

1.8 |

4.4 |

1.4 |

3.15 |

11.1 |

1410 |

245 |

4 |

0.71 |

54.5 |

|

SST59D315X |

1.8 |

2.9 |

2.1 |

1.40 |

5.1 |

1410 |

245 |

4 |

0.71 |

54.5 |

|

SST59D320X |

1.8 |

2.4 |

2.8 |

0.85 |

3.0 |

1440 |

245 |

4 |

0.71 |

54.5 |

|

SST59D510X |

1.8 |

6.7 |

1.4 |

4.80 |

19 |

2400 |

470 |

4 |

1.11 |

77.5 |

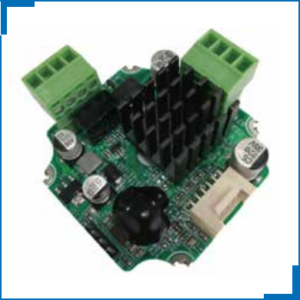

CAN DC Push Rod Controller

Features

Electric Interface

Features

– Industrial CAN Bus

– Free networking

– Independent control

– Real-time Current Detection

– Current foldback design

– Locked Rotor Amps configurable

– Automatic stop if any failure

– Positive/Negative control and speed adjustable

– Heartbeat detection supported

– Dynamic address allocation

Electric Interface